Understanding Pneumatic Ball Valves and Their Applications Pneumatic ball valves are essential components in modern indu...

LEES MEER

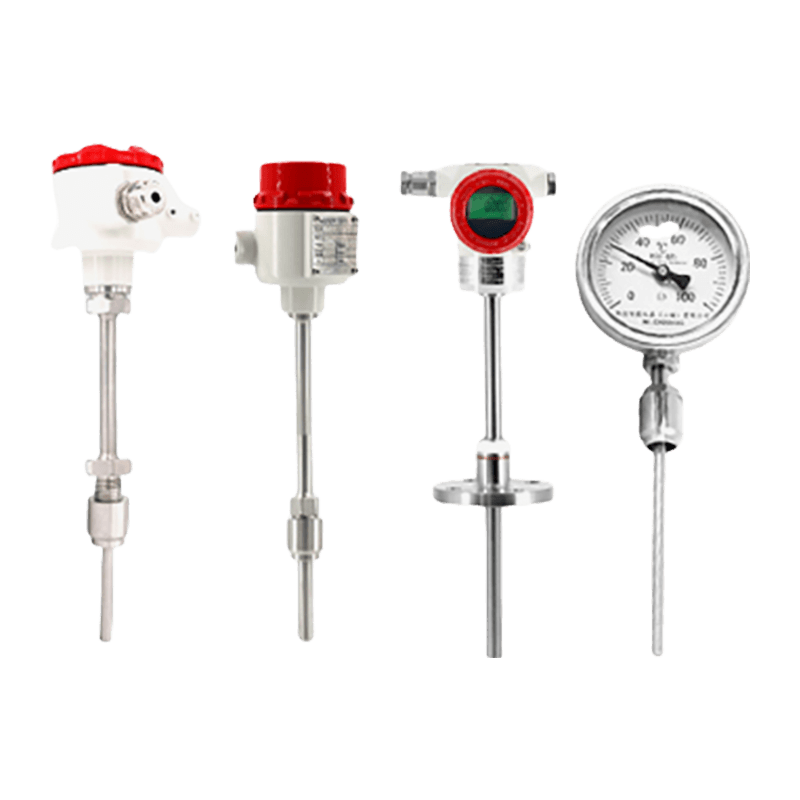

Temperatuur instrumenten Leveranciers

-

De FvLuoky FT100 slimme tweedraads temperatuurtransmitter kan worden aangesloten op RTD's of thermokoppels, voert linearisatie en compensatie

FvLuoky biedt een uitgebreid assortiment temperatuurinstrumenten, waaronder temperatuurzenders en slimme zenders. Elk instrument is gebouwd met hoogwaardige materialen en geavanceerde technologie om nauwkeurige en stabiele metingen in diverse industriële toepassingen te garanderen. Onze temperatuurinstrumenten zijn zorgvuldig gekalibreerd en getest en leveren betrouwbare prestaties onder extreme omstandigheden, zoals hoge of lage temperaturen en veeleisende omgevingen. Met een breed productportfolio en flexibele aanpassingsmogelijkheden worden FvLuoky-temperatuurinstrumenten veel gebruikt in de petrochemische, metallurgische, energie-, energie- en waterbehandelingsindustrieën, waardoor robuuste procescontrole en operationele veiligheid worden gegarandeerd. Of het nu gaat om routinematige monitoring of integratie in intelligente systemen, FvLuoky-temperatuurinstrumenten bieden precisie, betrouwbaarheid en prestaties op de lange termijn.

Vatten Valve Group, een wereldwijd gerenommeerde industriële automatiseringskleponderneming afkomstig uit Saarlen, Duitsland, is gespecialiseerd in onderzoek, ontwikkeling en productie van kernproducten zoals automatische kogelkranen, vlinderkleppen en regelkleppen. Door gebruik te maken van onze uitzonderlijke technologische expertise, leveren we innovatieve klepoplossingen en professionele technische ondersteuning aan cruciale industrieën, waaronder de energie-, chemische, waterzuiverings-, farmaceutische en voedselverwerking.

Als Temperatuur instrumenten Leveranciers En Temperatuur instrumenten Fabriek, De groep beschikt over vier ultramoderne productievestigingen op strategische locaties in Shanghai, Tianjin, Lishui en Jiaxing, China. Om internationale markten beter te kunnen bedienen, hebben we vestigingen geopend op belangrijke strategische locaties, waaronder het Verenigd Koninkrijk, Turkije, Wit-Rusland, Saoedi-Arabië en Indonesië. De opening van ons kantoor in Indonesië versterkt onze dienstverlening in de Zuidoost-Aziatische markt aanzienlijk en garandeert tijdige en efficiënte technische ondersteuning en service voor lokale partners en klanten.

Geworteld in de Duitse traditie van precisieproductie, blijft Vatten Valve zich richten op automatische regelkleppen en houdt zich daarbij strikt aan internationale kwaliteitsnormen. Voorzien Aangepast Temperatuur instrumenten. Wij zetten ons in voor continue innovatie en bieden onze klanten producten met superieure prestaties, professionele technische ondersteuning en complete oplossingen voor vloeistofregeling, waarmee zij complexe industriële uitdagingen op het gebied van vloeistofregeling kunnen aanpakken.

-

-

Inleiding tot elektrische kogelkranen Elektrische kogelkranen zijn cruciale componenten in moderne vloeistof...

LEES MEER -

Begrijpen wat membraankleppen zijn Membraankleppen zijn stroomregelapparaten die een flexibel diafragma gebr...

LEES MEER -

Het belang van regelkleppen in de industriële automatisering en het onderhoud van hun klepstandstellers. Tegen...

LEES MEER -

Inzicht in elektrische schuifafsluiters Elektrische schuifafsluiters zijn geautomatiseerde apparaten die zij...

LEES MEER

Calibration Techniques for Temperature Instruments

Accurate calibration of temperature instruments are essential for precise process control. Common methods include fixed-point calibration, where instruments are compared against stable reference temperatures such as melting points of pure substances, and comparison calibration, using highly accurate reference thermometers. Regular calibration helps detect drift in sensors, ensuring that readings remain within specified tolerances. In critical industries like pharmaceuticals or chemical processing, calibration intervals are determined based on process sensitivity and regulatory requirements.

Selection Criteria for Industrial Temperature Transmitters

When choosing temperature transmitters for industrial applications, factors such as process temperature range, sensor type compatibility, and environmental conditions must be considered. Transmitters must provide linearized output signals compatible with control systems and have sufficient accuracy and stability under varying process conditions. Additional features, such as HART communication capability, explosion-proof certification, and remote diagnostics, enhance operational reliability and ease of maintenance in complex or hazardous environments.

Impact of Sensor Placement on Temperature Measurement Accuracy

The placement of temperature sensors within a process greatly affects measurement accuracy. Sensors must be positioned in areas with representative fluid or gas flow to avoid temperature stratification or localized hot spots. Immersion depth, proximity to walls, and thermal lag caused by sensor mounting can introduce errors. Proper selection of thermowell length and material minimizes response time discrepancies and ensures that the transmitter receives accurate thermal data for process monitoring and control.

Common Signal Transmission Methods for Temperature Transmitters

Temperature transmitters convert sensor readings into standardized electrical signals for monitoring and control. Typical output methods include 4–20 mA current loops, 0–10 V voltage signals, and digital protocols such as HART or Modbus. The choice of transmission method affects noise immunity, wiring distance, and integration with control systems. Current loop transmission is widely preferred for long-distance applications due to its resistance to signal degradation and electrical interference.

Comparative Table: RTD vs. Thermocouple Temperature Instruments

Resistance Temperature Detectors (RTDs) and thermocouples are the most commonly used temperature sensors in industry. The table below highlights their differences:

| Feature | RTD | Thermocouple |

| Accuracy | High, ±0.1–0.5°C | Moderate, ±1–2°C |

| Temperature Range | -200°C to 850°C | -200°C to 1800°C |

| Stability | Excellent long-term stability | Good, may drift over time |

| Cost | Higher | Lower |

Temperature Transmitter Signal Conditioning and Accuracy Enhancement

Modern temperature transmitters include signal conditioning circuits that linearize sensor outputs, compensate for cold junction effects, and filter electrical noise. Advanced transmitters implement digital linearization for RTDs or thermocouples, improving accuracy over a wide range. Some devices also provide self-diagnostics, alerting operators to sensor drift, open circuits, or short circuits, which helps maintain reliable process control and reduces the risk of downtime caused by faulty measurements.

Maintenance Best Practices for Temperature Instruments

Regular maintenance of temperature instruments ensures measurement consistency and prolongs service life. Practices include periodic verification against reference standards, cleaning sensor surfaces, checking thermowell integrity, and inspecting transmitter wiring and connections. In harsh environments, protective enclosures and sensor coatings prevent corrosion and mechanical damage. Documenting calibration results and maintenance actions allows traceability and facilitates process compliance audits.

- Verify sensor response time periodically to detect sluggish behavior.

- Inspect thermowells for erosion or cracks that may affect readings.

- Clean electrical contacts and terminals to prevent signal degradation.

- Maintain records of calibration for regulatory compliance and performance tracking.

Environmental Effects on Temperature Measurement Accuracy

External factors such as vibration, ambient temperature fluctuations, and electromagnetic interference can influence temperature measurement accuracy. Mechanical isolation, shielding, and proper grounding of transmitters help mitigate these effects. Installing sensors away from heat sources or cooling drafts ensures stable readings. Additionally, selecting transmitters with wide operating temperature ranges and robust construction improves reliability in industrial environments with variable conditions.

Digital Communication Integration for Temperature Transmitters

Temperature transmitters with digital communication capabilities, such as HART, Modbus, or Foundation Fieldbus, offer real-time data access, remote calibration, and integration with control systems. These digital transmitters enable precise monitoring, logging, and predictive maintenance, reducing the risk of process deviations. Multi-sensor transmitters can aggregate data, providing better visibility and allowing centralized control of complex processes with minimal wiring and enhanced diagnostic capabilities.